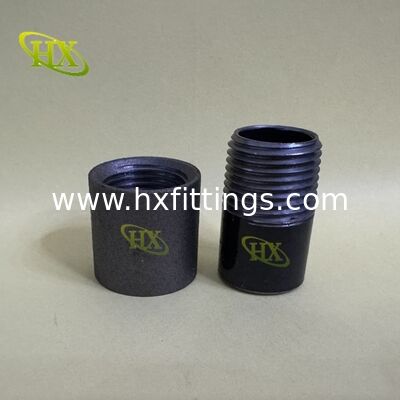

1/4 Black steel pipe socket with BSP screwed female socket | manufacturer

Our 1/4" Black Steel Pipe Socket with BSP Screwed Female Socket is a precision-engineered pipe fitting designed for connecting two male-threaded pipes in industrial and commercial applications. This high-quality socket features British Standard Pipe (BSP) female threads on both ends, manufactured from durable carbon steel with a protective black oxide finish. The socket complies with international standards including BS EN 10241 and ISO 7-1, ensuring reliable performance in plumbing, hydraulic systems, pneumatic equipment, and industrial machinery. With pressure ratings up to 3000 PSI and temperature resistance from -20°C to 300°C, this black steel socket provides exceptional durability and leak-proof connections in demanding environments. As a professional manufacturer, Cangzhou Hongxin guarantees precise threading, consistent quality, and competitive pricing for all your pipe fitting needs.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | 1/4" Black Steel Pipe Socket with BSP Female Threads |

| Thread Type | BSP (British Standard Pipe) Female Threads |

| Thread Standard | BSPP (G) or BSPT (R) as per requirement |

| Size | 1/4" (DN8) |

| Material | Carbon Steel (Grade: S235JR, S355JR or equivalent) |

| Finish | Black Oxide (Anti-corrosion Treatment) |

| Pressure Rating | Up to 3000 PSI (20.6 MPa) |

| Temperature Range | -20°C to 300°C (-4°F to 572°F) |

| Wall Thickness | Schedule 80 Standard (3.2mm minimum) |

| Standards Compliance | BS EN 10241, ISO 7-1, ASME B1.20.1 |

| Hex Size | 19mm (for standard wrench fitting) |

| Working Medium | Water, Oil, Gas, Air, Non-corrosive Fluids |

Manufacturing Excellence

Precision Engineering

-

CNC machining for accurate thread cutting

-

Quality control at every production stage

-

Batch testing for consistency

-

ISO 9001 certified manufacturing process

Quality Assurance

100% thread inspection with certified gauges

Dimensional verification using calibrated tools

Material testing and certification

Visual inspection for surface quality

Ordering Information

Minimum Order Quantity: 500 pieces

Lead Time: 15-25 working days

Packaging: Export-standard packaging

Sample Availability: Available upon request

Custom Orders: Special requirements welcome