1/2 Inch Black Welding Pipe Nipple Size Chart | China Factory - Cangzhou Hongxin

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

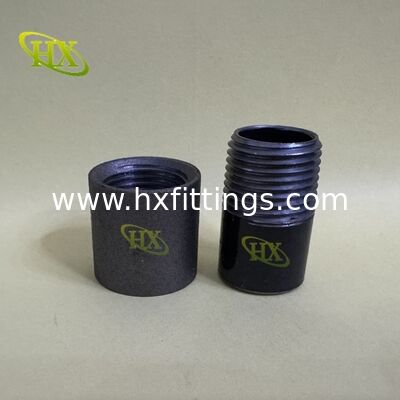

xCangzhou Hongxin is a leading China-based manufacturer specializing in precision 1/2 inch black welding pipe nipples. These industrial-grade fittings are designed with one end featuring standard threading and the opposite end prepared for welding, creating permanent, high-strength connections in piping systems. Our black finish provides natural corrosion protection while maintaining cost-effectiveness for various industrial applications.

Key Specifications

-

Nominal Size: 1/2 inch (DN15)

-

Thread Type: NPT (National Pipe Taper) standard

-

Material: ASTM A53/A106 carbon steel

-

Finish: Black (mill finish)

-

Design: One threaded end, one welding-ready end

-

Pressure Rating: Suitable for medium to high-pressure systems

-

Temperature Range: -20°F to 750°F (-29°C to 399°C)

Complete Size Chart - 1/2" Black Welding Pipe Nipple

| Parameter | Dimension | Tolerance | Standard |

|---|---|---|---|

| Nominal Pipe Size | 1/2 inch | - | ANSI/ASME B36.10 |

| Outside Diameter (OD) | 21.34 mm (0.840 in) | ±0.5% | ASTM A53 |

| Thread Specification | NPT 1/2" | ANSI B1.20.1 | ASME B16.11 |

| Wall Thickness Options | |||

| - Schedule 40 (STD) | 2.77 mm (0.109 in) | ±10% | ASTM A106 |

| - Schedule 80 (XS) | 3.73 mm (0.147 in) | ±10% | ASTM A106 |

| - Schedule 160 | 4.78 mm (0.188 in) | ±10% | ASTM A106 |

| Welding End Preparation | Bevel 37.5° | ±2.5° | ASME B16.25 |

| Standard Lengths | |||

| - Close Nipple | 50 mm (2.0 in) | ±1.5 mm | Custom |

| - Short Nipple | 75-100 mm (3-4 in) | ±2.0 mm | Custom |

| - Long Nipple | 150-200 mm (6-8 in) | ±3.0 mm | Custom |

| Thread Length | 15 mm (0.59 in) | ±1.0 mm | ANSI B1.20.1 |

Material Specifications

-

Base Material: Carbon Steel ASTM A53 Grade B / A106 Grade B

-

Chemical Composition:

-

Carbon (C): 0.30% max

-

Manganese (Mn): 0.29-1.06%

-

Phosphorus (P): 0.035% max

-

Sulfur (S): 0.035% max

-

-

Mechanical Properties:

-

Tensile Strength: 415 MPa min

-

Yield Strength: 240 MPa min

-

Hardness: 137 HB max

-

Applications

-

Plumbing Systems: Water supply and drainage connections

-

Industrial Piping: Process lines and equipment connections

-

HVAC Systems: Heating and cooling installations

-

Fire Protection: Sprinkler system components

-

Manufacturing: Equipment and machinery piping

Quality Assurance

-

100% dimensional inspection

-

Thread gauge verification per ANSI B1.20.1

-

Material certification per EN 10204 3.1

-

Visual inspection for surface defects

-

Hydrostatic testing available upon request

Manufacturing Process

-

Raw Material Selection: Certified carbon steel pipes

-

Precision Cutting: CNC cutting to exact lengths

-

Thread Machining: CNC threading to NPT standards/BSPT standards

-

End Preparation: Beveling for welding readiness

-

Surface Treatment: Cleaning and black finish application

-

Quality Control: Multi-stage inspection process

-

Packaging: Industrial-grade packaging for export

Ordering Information

-

Minimum Order Quantity: 500 pieces standard sizes

-

Lead Time: 15-20 days for standard orders

-

Customization Available: Special lengths, wall thicknesses

-

Packaging Options: Bulk boxes or customized packaging

-

Sample Policy: Samples available with minimal charge

Why Choose Hongxin Factory?

-

30+ Years Manufacturing Experience

-

ISO 9001:2015 Certified Facility

-

Competitive Factory-Direct Pricing

-

Custom Engineering Capabilities

-

Global Export Expertise

-

Comprehensive Quality Documentation

FAQ

Q: What is the difference between Schedule 40 and Schedule 80?

A: Schedule 80 has thicker walls and higher pressure rating than Schedule 40.

Q: Can you supply metric threaded versions?

A: Yes, we manufacture BSPT and metric threads upon request.

Q: Are these nipples suitable for steam applications?

A: Yes, with proper material selection and pressure rating verification.

Q: Do you provide material test certificates?

A: Yes, full material certification with every shipment.

![]()