What's a steel pipe nipple ?| Cangzhou Hongxin

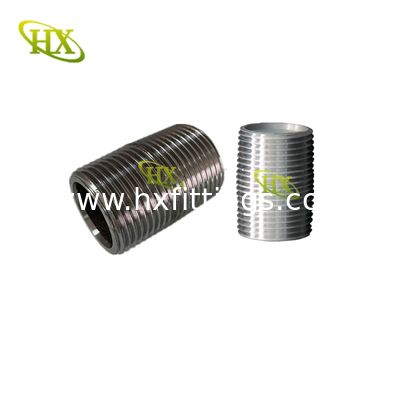

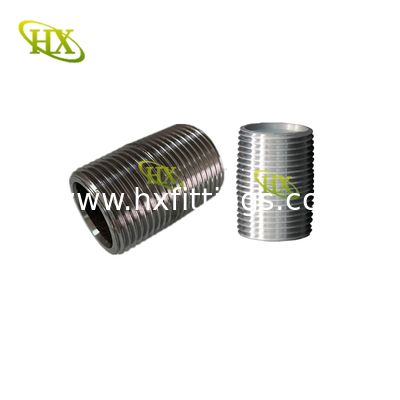

A steel pipe nipple is a short pipe section with external threads (male threads) on both ends or one end, designed to connect two pipes or fittings in plumbing and fluid transfer systems. These essential components are available with various thread types, including NPT and BSP, and can be manufactured from different materials to suit specific application requirements. As a leading pipe nipple manufacturer and supplier, Cangzhou Hongxin offers a comprehensive range of standard and custom-sized steel pipe nipples.

Types of Steel Pipe Nipples

Steel pipe nipples can be classified based on material and design:

By Material:

- Carbon Steel Nipple

Includes galvanized and black steel nipples

Provides reliable, durable connections for fluid transfer

Galvanized Nipple: Zinc-coated for enhanced corrosion resistance in moist or chemical environments

Black Pipe Nipple: Uncoated steel with basic corrosion resistance

- Stainless Steel Nipple

Grades 304 and 316 offer excellent mechanical properties

Resistant to corrosion, high pressure, and temperature variations

Ideal for demanding industrial applications

By Design:

- Welding Nipple

One threaded end, one end for welding

Used in high-pressure applications (oil/gas pipelines, chemical plants)

- Seamless Pipe Nipple

No welding seams, enhanced strength

Common in HVAC, chemical processing, and oil/gas industries

- Reducer Nipple

Connects pipes of different diameters

Maintains pressure integrity with BSP, BSPT, NPT threads

- Barrel Nipple

Straight pipe with threaded ends and smooth middle section

Connects same-diameter pipes

- Hex Nipple

Hexagonal center for easy wrench tightening

Ensures secure, leak-resistant connections

- Close Nipple / Running Nipple

Fully threaded for tight connections between fittings

Minimal exposed section after installation

- Hose Nipple

One threaded end, one hose barb end

Connects threaded pipes to smooth hoses

- Flange Nipple

Combines nipple and flange for secure, bolted connections

Raised flange ensures leak-proof performance

Supply Range at Cangzhou Hongxin

Materials: Carbon steel, Stainless steel

Standards: ASTM A733, DIN2982, BS EN10241

Dimensions: 1/8" to 8" (DN6 to DN150)

Finishes: Black or galvanized

Pressure Rating: Varies by size, construction, and application

Pipe Nipple Applications

Steel pipe nipples are essential in multiple industries:

Chemical processing

Petrochemicals

Pharmaceuticals

Food & beverage

Shipbuilding

Waste incineration

Machine building

Architecture

Semiconductor manufacturing

Pipe Nipple Quality Standards

Cangzhou Hongxin manufactures pipe nipples to international standards:

ASTM A733 Standard

Carbon Steel Pipe Nipple

Material: ASTM A53/A106

Thread: ANSI/ASME B 1.20.1

Stainless Steel Pipe Nipple

Material: ASTM A312 (304/316)

Thread: ANSI/ASME B 1.20.1

DIN2982, BS EN10241 Standards

Material: DIN2441/DIN2440 or BS1387 seamless/welded pipe

Thread: DIN259/DIN2999 or ISO 7/1/BS 21

Material GradesCarbon Steel: ASTM A105, ASTM A53 GR. A & B, API 5L GR. B

Stainless Steel: ASTM A182 (304, 316), ASTM A312/A403 (TP304, TP316)

Why Choose Cangzhou Hongxin?

Manufacturing Expertise: Established reputation for quality since inception

Quality Focus: Survival by quality, development by reputation

Wide Applications: Products used in gas, oil, water, fire protection, HVAC, mining, and fluid transportation

Custom Solutions: Tailored sizes and specifications to meet unique project needs

![]()